Blower

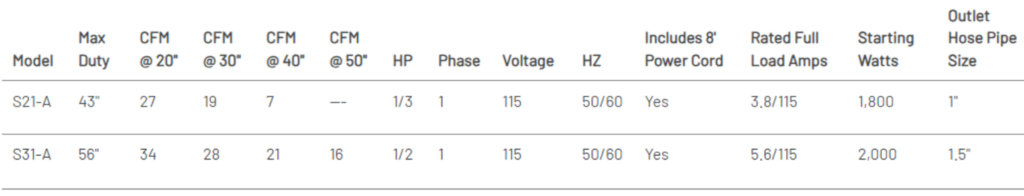

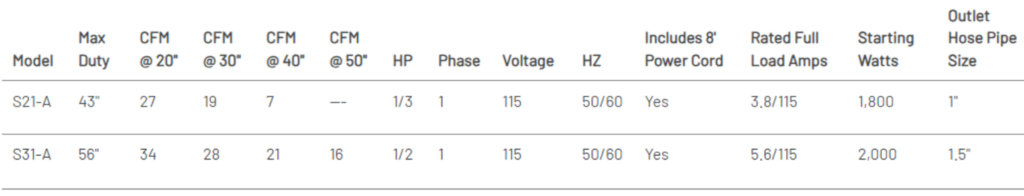

There is only one moving part in the blower: a dynamically balanced impeller that is attached directly to the motor shaft.Because the rotating impeller doesn't touch any of the blower's components, there's no wear, no vibration, no seals and no lubrication.The aluminum blower housing, impeller, and cover make major components corrosion resistant that promotes an extended product life.High altitude affects the blower's performance.Deduct 4% of volume and pressure for every 1,000' (300 m) elevation above sea level.The 3,450-rpm motors used on these regenerative blowers reach full speed after about ten seconds.Use starting watts to size generators and use full load amps to size breakers.

Motor

The motors feature permanently sealed ball bearings that protect against weather, dirt and moisture, particularly useful in humid aquaculture environments.These motors run cool and handle a wide range of power variations.Permanently sealed bearings incorporate polyurea grease to extend bearing life and offer superior resistance to washout, rust, and corrosion.Thermal over load protection protects motor windings from damage should the blower become stalled during operation.Additionally, thermal over load protection switches automatically reset when single-phase motor windings cool down to a safe level of operation.All models will operate on both 50 and 60 cycle.

Optional Inlet Kits

Inlet filter kit features low-restriction, washable air filters, a PVC elbow and pipe.Kits sold separately.

Features

• Oil-less operation ensures discharge air remains free of contamination

• Very few moving parts and no wear parts minimize downtime and lessen operating noise levels

• Mounts in any plane providing flexibility when mounting/integrating the blower into a system

• Simple to maintain – Replace the motor bearings after three years of continuous operation and wash the inlet air filters as needed

Note: All 1/3 HP Models and smaller ship Ground